Tel:+86-18118029715 Email:mary@cnhengjiu.com

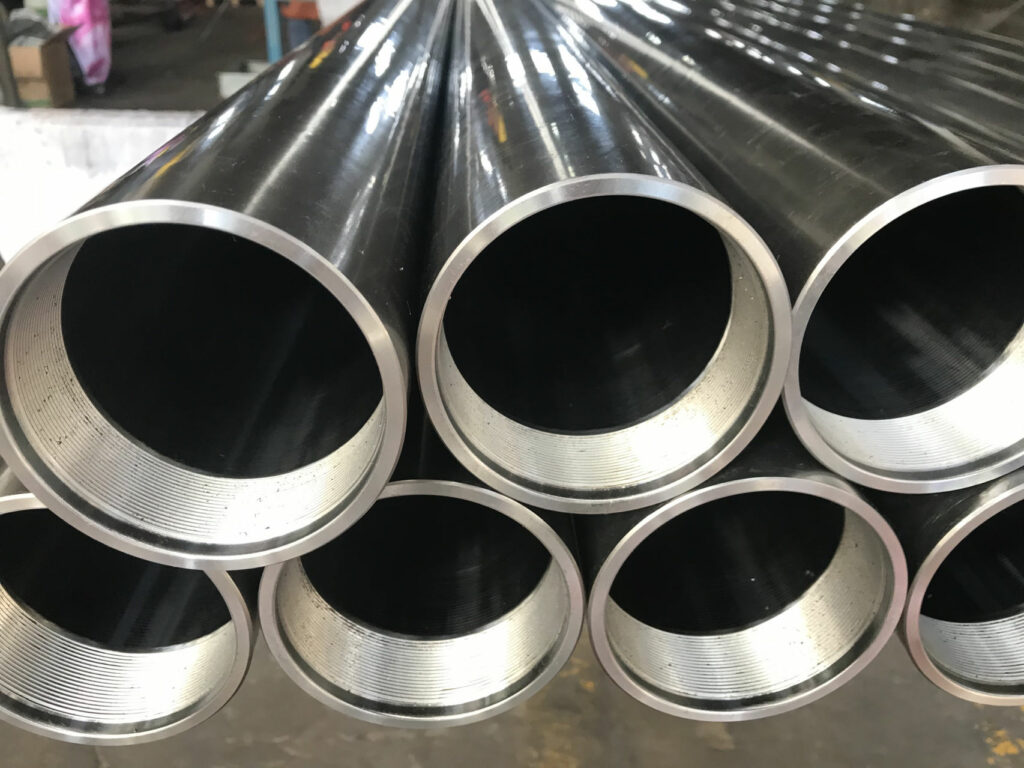

Specifically designed for ESP systems in oil production, with high corrosion resistance and dimensional consistency for harsh environments.

We export to more than 10 countries around the world, such as Russia, Saudi Arabia, the United States, Colombia and so on.

20 years of production experience.

ESP Tubing for Electrical Submersible Pumps

| Items | Details |

|---|---|

| Standard | EN10305-1, DIN2391, GB/T 3639 |

| Steel grade | ST52/16Mn/E355,C1026/25Mn,C1020/20#,45#,27SiMn,stainless steel 316L,304 TP321/ 304/2205/45#/13Cr/Super 13Cr/40Cr |

Delivery Condition: | BK, BK+S, GBK, NBK,Thread |

Normal Types | 338,400,513,538,562,675,862,950 |

Length | 3 – 12 m |

| ID(mm) | TOLERANCE(mm) | |||

| H7 | H8 | H9 | H10 | |

| ≦30 | +0.021/0 | +0.033/0 | +0.052/0 | +0.084/0 |

| 30 – ≦50 | +0.025/0 | +0.039/0 | +0.062/0 | +0.100/0 |

| 50 – ≦80 | +0.030/0 | +0.046/0 | +0.074/0 | +0.120/0 |

| 80 – ≦120 | +0.035/0 | +0.054/0 | +0.087/0 | +0.140/0 |

| 120 – ≦180 | +0.040/0 | +0.063/0 | +0.100/0 | +0.160/0 |

| 180 – ≦250 | +0.046/0 | +0.072/0 | +0.115/0 | +0.185/0 |

| 250 – ≦315 | +0.052/0 | +0.081/0 | +0.130/0 | +0.210/0 |

| 315 – ≦700 | +0.057/0 | +0.089/0 | +0.140/0 | +0.230/0 |

QUESTION 1: WHAT IS THE DELIVERY TIME OF HYDRAULIC HONED TUBES?

Answer: To protect the inner surface of the honed lD tubing, we will plug each tube with tubecaps on each end, the tube caps usually are plastic in green or yellow. adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Other Available Products of Honed Tubes

» E355 (EN 10305-1) Honed Tubes Supplier

» St52-3 (DIN 2391) Honed Tube Manufacturer

» H8 (EN ISO 286-2) Honed Tube Manufacturer

» AISI / SAE / ASTM Honed Tubes Exporter

» +SR (EN 10305-1) Honed Tubing Stockiest

» Stainless Steel Honed Tube Manufacturer

» SS 304 Honed Tube Manufacturer

» SS 316 Honed Tube Manufacturer

» SS 304L Honed Tube Manufacturer

» SS 316L Honed Tube Manufacturer

» ST52 Honed Tube Manufacturer

» Mild Steel Honed Tube Manufacturer

» Carbon Steel Honed Tube Manufacturer

» BK+S (DIN 2391) Honed Tubes

» E355 Honing Tubes Stockholder

» Hiqh Quality H8 Honed Tube

» UNI EN 10025 Fe510 Honed Tube

» Seamless Honed Tube Dealer

JIANGSU YING NAISI MACHINERY MANUFACTURING CO.,LTD

Address: No.5 Industrial Avenue, Panjia Industrial Zone, Xueyan Town,Wujin District.

Changzhou City, Jiangsu Province,China.

Email:mary@cnhengjiu.com

redsuncream@gmail.com

Get Started Now!

HOT PRODUCTS

MAIN PRODUCTS

Powered by Jiangsu YingNaiSi Machinery Manufacturing Co.,Ltd