ESP Tubing for Oilfields: Key Specs You Need to Know

In the oil and gas industry, Electric Submersible Pumps (ESP) play a vital role in artificial lift systems. One of the most critical components in an ESP system is the tubing that houses and protects the downhole pump cable, supports mechanical integrity, and ensures stable fluid production. Choosing the right tubing is crucial for operational efficiency and longevity.

In this blog, we’ll walk you through the key specifications to consider when selecting ESP tubing for your oilfield projects.

1. Material Grade Matters

ESP tubing must withstand high pressure, corrosive fluids, and temperature fluctuations. Common materials include:

Carbon steel (e.g., AISI 1026, 25Mn) – Cost-effective, suitable for general applications.

Stainless steel (e.g., AISI 304, 316L, 321) – Ideal for high-corrosion environments.

Customized GOST materials – For Russian and Eastern European clients.

Always ensure material certifications (e.g., GOST 21474-75, ASTM, EN standards) are provided by your supplier.

2. Precision Tolerances

To meet the tight tolerances required in ESP systems, cold drawn or cold rolled processes are preferred. Key parameters include:

OD tolerance: ±0.2mm or tighter

Wall thickness tolerance: ±10% or as per customer request

Straightness: ≤0.5mm per meter

Ovality and eccentricity: controlled as per ESP system specifications

These tolerances help reduce vibration, improve sealing, and ensure smooth assembly in downhole systems.

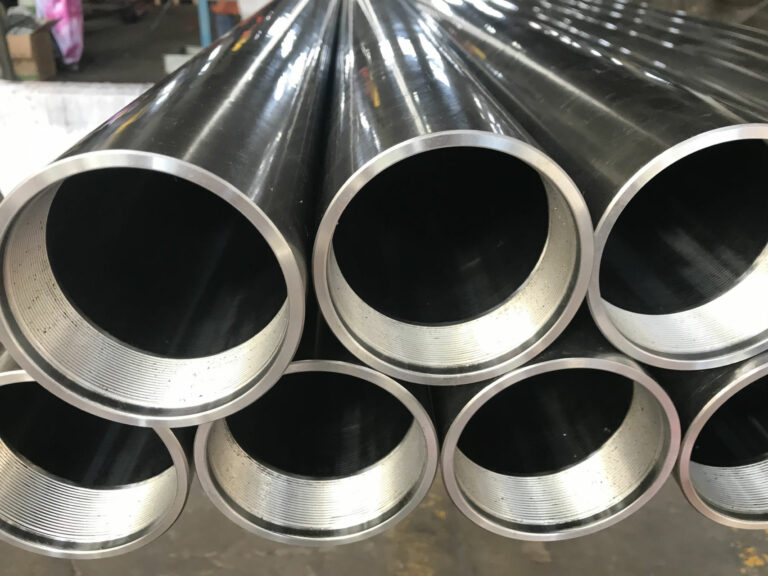

3. Surface Condition & Finish

A smooth internal and external surface is crucial. Look for:

Annealed finish to ensure ductility and mechanical strength

Deburred and cleaned inner wall to avoid damaging cables or sensors

No rust, scale, or oil contamination

Your supplier should provide ultrasonic or eddy current testing upon request.

4. Length & End Processing

Tubing for ESP systems is often supplied in fixed lengths (e.g., 5.8m, 6m, 12m), and can be customized with:

Threaded & coupled ends

Beveled or plain ends

Protective caps and packaging

Some applications also require internal coating or phosphating to enhance corrosion resistance.

5. Mechanical Properties

Ensure your tubing supplier provides full mechanical property reports, including:

Yield strength

Tensile strength

Elongation

Hardness (HRB/HRC)

These should align with project-specific technical requirements.

6. Quality Assurance & Documentation

A trustworthy supplier will provide:

Material Test Certificate (MTC)

Dimensional inspection report

Third-party inspection if needed

Traceability from raw material to finished tube

✅ Conclusion

Choosing the right ESP tubing is not just about the material — it’s about precision, performance, and reliability in extreme conditions. At Jiangsu Yingnaisi Machinery, we specialize in custom-made cold drawn seamless tubes for ESP applications. With over 15 years of export experience and compliance with GOST, ASTM, and ISO standards, we ensure the quality you need.

📩 Contact us today to discuss your ESP tubing project or request a sample!