Tel:+86-18118029715 Email:mary@cnhengjiu.com

Hard Chrome Plated Rods Manufacturer, Round Hard Chrome Plated Rod Supplier, SS Hard Chrome Plated rods Exporter, EN-8D Hard Chrome Plated Rods Stockist, C-45 Hard Chrome Plated Rods Dealer, Polished Hard Chrome Plated Rods

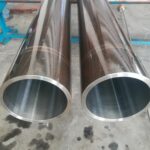

Jiangsu YNS is a leading manufacturer and supplier of Hard Chrome Plated rods. Hard chrome plated rods, often referred to as chrome plated bars or Chrome Plated Shaft, are essential metal components widely used in industrial applications. These rods are usually crafted from steel or similar metals and are treated through a specialized plating process. This process involves applying a layer of hard chrome to the surface, improving their durability and performance. This technique, commonly known as hard chrome plating or industrial hard chrome plating, makes sure the rods meet the demands of various industries.

Features

Product Specifications

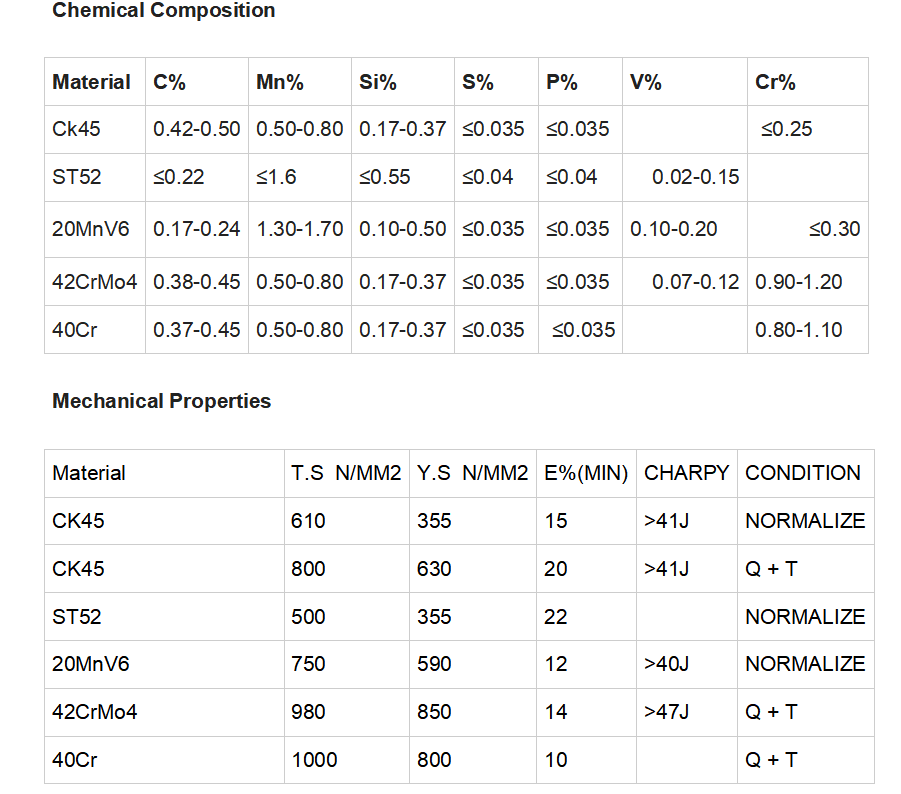

| Material Grade | CK-45/AISI C1050, AISI C1060, AISI 4340 (SAE), En9 |

|---|---|

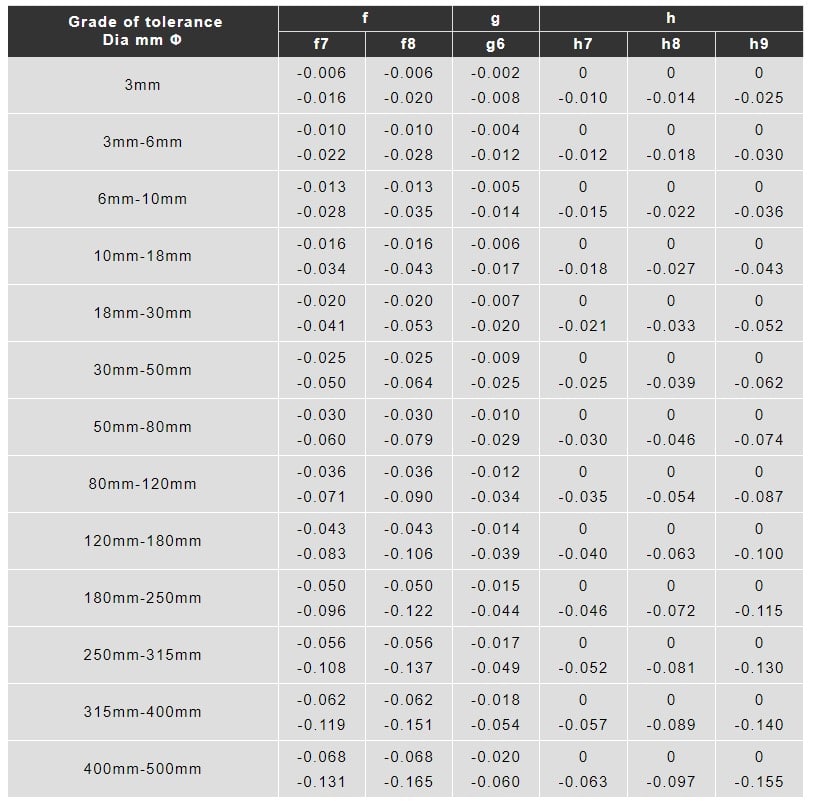

| Tolerance | ISO F7, F8 |

| Single Piece Length | 6 meter, 3 meter |

| Size/Diameter | 4 mm – 200 mm |

| Thickness/Diameter | 6 mm upto 200 mm |

| Finish | Chrome Plating |

| Straightness | 0.1/1000 |

| Surface Finishing | Polished & brush |

| Surface Roughness | Ra 0.2 Microns or Better |

| Chrome Plating Thickness | 25 Micron minimum |

| Chrome Layer Hardness | > HV-900-1150 (67 HRC) |

Packing: Wooden case

WE ALSO PRODUCE:

Hard Chrome Plated Bar

Skived Roller Burnished Tube;

Chrome Plated Tube;

Ready to hone tube;

Large size honed bore tube;

Seamless cold drawn tube

QUESTION 1: WHAT IS THE DELIVERY TIME OF HYDRAULIC HONED TUBES?

Answer: To protect the inner surface of the honed lD tubing, we will plug each tube with tubecaps on each end, the tube caps usually are plastic in green or yellow.

Other Available Products of Honed Tubes

» E355 (EN 10305-1) Honed Tubes Supplier

» St52-3 (DIN 2391) Honed Tube Manufacturer

» H8 (EN ISO 286-2) Honed Tube Manufacturer

» AISI / SAE / ASTM Honed Tubes Exporter

» +SR (EN 10305-1) Honed Tubing Stockiest

» Stainless Steel Honed Tube Manufacturer

» SS 304 Honed Tube Manufacturer

» SS 316 Honed Tube Manufacturer

» SS 304L Honed Tube Manufacturer

» SS 316L Honed Tube Manufacturer

» ST52 Honed Tube Manufacturer

» Mild Steel Honed Tube Manufacturer

» Carbon Steel Honed Tube Manufacturer

» BK+S (DIN 2391) Honed Tubes

» E355 Honing Tubes Stockholder

» Hiqh Quality H8 Honed Tube

» UNI EN 10025 Fe510 Honed Tube

» Seamless Honed Tube Dealer

JIANGSU YING NAISI MACHINERY MANUFACTURING CO.,LTD

Address: No.5 Industrial Avenue, Panjia Industrial Zone, Xueyan Town,Wujin District.

Changzhou City, Jiangsu Province,China.

Email:mary@cnhengjiu.com

redsuncream@gmail.com

Get Started Now!

HOT PRODUCTS

MAIN PRODUCTS

Powered by Jiangsu YingNaiSi Machinery Manufacturing Co.,Ltd